Capabilities

GEAR Sizes

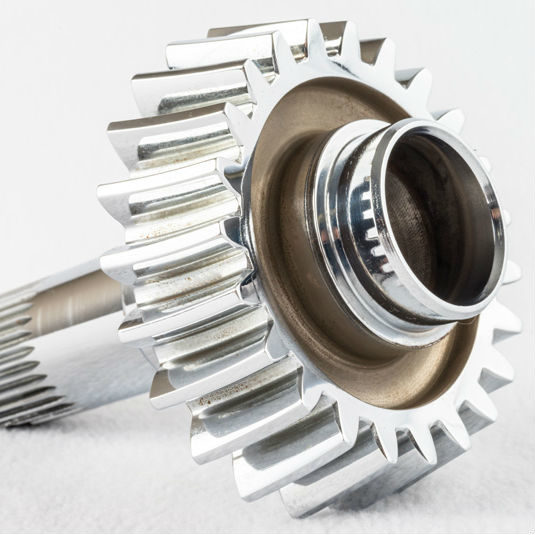

Arrow is equipped for a full range of machining capabilities to meet customer needs.

Isotropic Superfinishing

The surface finish of gear teeth is directly related to the service life and quality of aerospace gearing. So Arrow has added the capability of Isotropic Superfinishing.

Heat Treat

Arrow’s heat treat department, which is Nadcap certified, is equipped for a full range of heat treating operations.

Gearbox Assembly

An aspect of Arrow Gear that is not as widely known as our loose gearing expertise is our capability for producing complete gearboxes.

Other Machining

Arrow is equipped with a full range of machining capabilities for the production of high precision gears such as turning, broaching, inertia welding, I.D. grinding, O.D. grinding, and lapping.