Ground Tooth Stock Gears

Ground Tooth Stock Gear

Ground Tooth Stock Gears Quality

Our ground tooth, stock gears are carburized, hardened and ground to meet AGMA Q11.

Stock Ground Tooth Gears

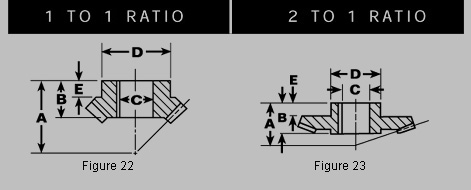

Arrow Gear Company was the first gear manufacturer to offer ground tooth spiral bevel gears from stock. The most popular sizes of 1:1 and 2:1 ratios are currently available for timesaving, off-the-shelf delivery.

Every stock ground tooth gear is designed and manufactured to fulfill the following requirements for discriminating gear buyers.

Speeds in Excess of 8,000 SFPM

Ground tooth spiral bevel gears should be used for speeds exceeding 8000 surface feet per minute. Ground tooth spiral bevel gears make velocity factor devaluation unnecessary. (See Rating Data.) A constant velocity factor of 1.00 means you transmit more torque or horsepower . . . up to 30% more with the same size gear and pinion.

Reduce Gear Noise

Ground tooth spiral bevel gears are a design "must" at high speeds to reduce the decibel level of your gear box. Tooth contact ratios are maintained to a minimum of 2.0 to assure quiet operations.

Eliminate Positioning Errors

To achieve near "zero" positioning error, designers and manufacturers of radar systems, navigational gear, printing presses and machine tools specify ground tooth spiral bevel gears.

Standard Stock Spiral Bevel Gear

Higher Quality

All Arrow ground tooth spiral bevel gears are manufactured to AGMA Quality Number 11 or better.

High Capacity

Have your gear capacity requirements outgrown your present housing and mountings? Eliminate unnecessary redesigning or gearbox size increases. Investigate the possible use of ground tooth spiral bevel gears for increased capacity. All Arrow ground tooth gears are shot peened for additional fatigue life.

Uniform Load-Carrying Capabilities

Grinding gear teeth corrects heat treat distortion to minimize tooth spacing errors and increase load capacity.

Arrow Gear has a full variety of ground tooth stock gears for our customer to choose from.

1:1 and 2:1 Ratios

More information is on page 13 of our Stock Gear Catalog. Click HERE to download a PDF version of that page.